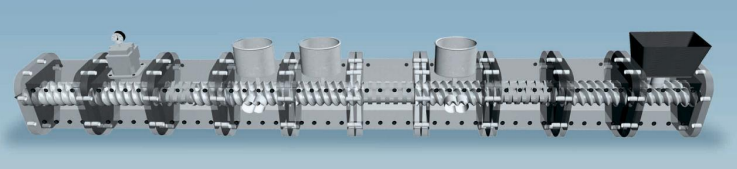

Effective cleaning of

twin screw extruder parts, including the twin screw element, twin screw barrel, and twin screw shaft, is crucial for maintaining optimal performance. The process involves careful steps to ensure thorough removal of residues without damaging the components. Below are the detailed steps and precautions for cleaning the extruder screw and barrel.

Cleaning the Extruder Screw

The efficient active cleaning materials can be used for cleaning the twin screw element and the screw shaft of the extruder. The process involves several steps:

1.Manual Addition of Machine-Washing Materials:

-

Begin by adding the cleaning materials manually from the cutting mouth until the color of the extrusion strip matches that of the washing machine materials.

-

Stop adding materials and empty the existing material.

-

Halt the rotation of the twin screw extruder shaft.

2.Opening the Die Head:

-

Open the die head of the twin screw extruder and start the cleaning process.

3.Rotating the Extruder Screw:

-

Rotate the extruder screw to remove the orifice plate.

-

Discharge the residual cleaning material in the barrel and clean the orifice plate.

4.Observation and Manual Cleaning:

-

Stop the rotation and pull out the screw to check for cleanliness.

-

Manually remove any wastes on the screw element.

-

Reinstall the screw, add new materials, and clean the remaining machine-washing materials without removing the screw.

5.Reassembling:

Reinstall the twin screw extruder and the die head to complete the cleaning of the extruder screw.

Precautions for Cleaning the Extruder Screw

When using extruder cleaning materials, consider the following:

-

Temperature Control: Ensure the temperature is appropriate for the cleaning materials.

-

Charging Speed and Current Control: Avoid filling materials at once due to their high hardness, which can cause heavy friction and potential screw jamming.

-

Rotating Speed: Maintain a normal rotating speed to prevent material degradation.

-

Screw Barrel Clearance: Pay attention to the clearance to avoid damage.

Cleaning the Extruder Barrel

Cleaning the twin screw barrel or screw barrel is relatively easier but equally important.

-

Setting the Barrel Temperature:

-

Set the extruder barrel temperature at 200°C in preparation for cleaning.

-

Creating a Cleaning Tool:

-

Attach a circular steel brush to the drill pipe to create a cleaning tool.

-

Wrap the steel brush with a copper wire mesh.

-

Using Stearic Acid:

-

Sprinkle some stearic acid into the barrel or on the copper wire mesh of the cleaning tool before inserting it.

-

Manual Cleaning:

-

Turn on the electric drill and move the tool back and forth manually in the cylinder until movement is smooth and free of resistance.

-

Final Cleaning:

-

After removing the copper wire mesh, use a cotton cloth bundle to wipe back and forth in the cylinder.

-

Remove any residual cleaning resin or stearic acid to complete the cleaning.

Conclusion

Maintaining the cleanliness of

twin screw extruder parts, including the twin screw element, twin screw barrel, and twin screw shaft, is essential for optimal performance. Proper cleaning methods and precautions help ensure the longevity and efficiency of these components. Regular maintenance and thorough cleaning prevent buildup and potential damage, contributing to the smooth operation of the extruder.

By following these detailed steps and adhering to the outlined precautions, you can effectively clean and maintain your

twin screw extruder parts, ensuring they remain in excellent condition for continued use.